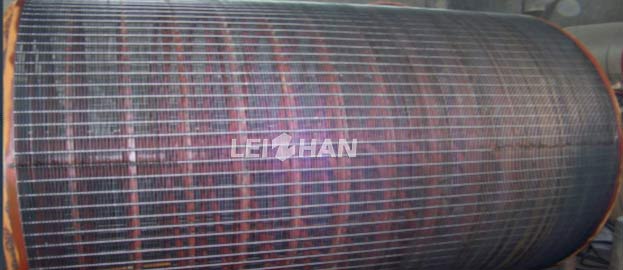

Cylinder Mold in Paper Making Line

The working principle of the cylinder mold is mainly to realize the discharge of water through the filtration and shaping of pulp. Through appropriate cylinder mold mesh size and structural design, the thickness and quality of the paper can be controlled. At the same time, the mesh cage has good drainage performance and can quickly remove moisture from the pulp, effectively improving the drying speed of the paper.

During the paper production process, the cylinder mold can efficiently filter the fibers in the pulp and drain out moisture, thereby improving the quality and thickness consistency of the paper. Compared with traditional paper forming methods, the cylinder mold can provide more precise forming control, with high reliability and strong stability. In addition, the cylinder mold has a strong structure, high durability, long service life, and can withstand high pressure and frequent use.

Leizhan can provide paper making machines and pulping machines of various outputs and models. Our high-quality paper making equipment is sold to various countries around the world and has received numerous praises. Do you have paper making needs? Welcome to contact us!

Email: whiteboardpapermachine@gmail.com

|